Categories

- All Categories

- 7 Cirrus Truck Campers

- 115 Dutchman and Vintage TaB Archives

- 5 Forum Rules

- 3 nüCamp & Forum Contacts

- 942 Air Conditioning & Refrigeration

- 2.6K Battery/Electrical & Solar

- 1.2K Camping & Travel

- 142 Events & News

- 219 Factory Comments

- 12 "FOR SALE" - New/Used Trailers

- 8 “FOR SALE" - Camping & Trailer Gear

- 2.3K Heating/Plumbing & Winterizing

- 133 Help - Computer & System

- 912 Introductions

- 406 Looking to purchase a trailer?

- 2.1K Modifications & Upgrades

- 1.4K Products and Accessories

- 393 Service/Maintenance & Recall Notices

- 37 Solo Travelers Hints & Tips

- 1 T@G Forum

- 71 Teardrop Groups & Links

- 72 Testimonials

- 909 Tips & Tricks

- 1.5K Trailer & Towing

- 27 Owners Manuals/PDF Files/Videos & Resources

- 62 üCamp Rally - News & Information

Alde Convector & Hose Rebuild, Useful Truma/Alde part numbers, and a Modest System Improvement

I own one of the early Tab 400s, built in the summer of 2017, purchased in the fall. The 3010 Alde came with Century Transfer Fluid. I replaced it after 4 years, in 2021, then again 2 years later, in 2023, still using the Century Fluid. That year, I noticed some minor-looking bulging at hose connections near the Alde and thought I should do a thorough inspection of convectors when I did the winter 2025 fluid change. A month ahead of my scheduled maintenance, the corrosion build-up in the last stub connector in the return tubing before the expansion tank caused the hose to tear and leak all over the cabin floor during a 2-week, 2,000 mile trip. Dang.

From Truma Corp (now owners of Alde), I ordered 80 29 mm spring band clamps, 30 plastic stub connectors, and 3 meters of Alde EPDM 22 mm I.D. hose.

I cut 4 corroded ends off of convectors. Two were on the convector under the bathroom, nearest the stub where the tube tore and leaked, almost at the expansion tank return. I suspect that the transfer fluid farthest from the pump refreshed less over time and allowed more corrosion.

As part of the system rebuild, I covered all convector ends and the check-valve stub connector, which is aluminum, with adhesive-lined heat-shrink tubing. I also double-clamped almost all connections, 3 centimeters in, and at the tube ends. I reused all 90 degree rubber tube pieces, which were undamaged, but cut the ends off of all straight hose pieces, many of which had bulged with corroded aluminum oxide. By using a new piece of rubber tubing for the longest (2 meters, approx.) section, then using my slightly shortened pieces for every shorter section, sequentially, I only needed to buy 3 meters of hose.

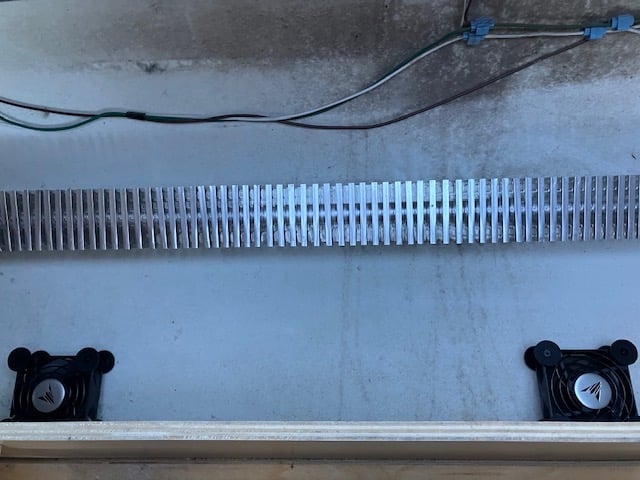

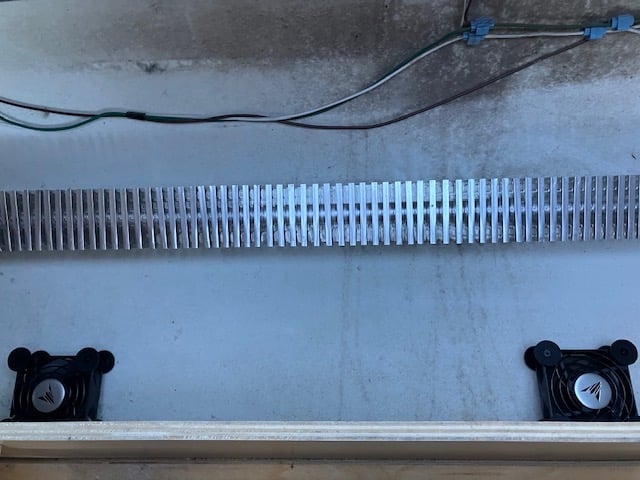

Finally, I added two switched 3.5” computer fans just below the convector at the back of the trailer, behind the bed. This convector is the longest, but often partially blocked by bedding, and I thought it could use a boost.

This job was time-consuming, involving lots of awkward and cramped working positions. However, I think it was much more feasible DIY, and I was more successful, because of the multiple contributions and threads of others who have serviced and repaired their Alde systems.

What follows are notes on the rebuild process and components used, along with references to other threads which were the source of the methods used and choices made.

Alde started using plastic stub connectors instead of aluminum ones, probably around 2021, when they recommended switching from Century Transfer Fluid to Rhomar Water RG-RTU-50, aka Truma/Alde Transfer Fluid. This change eliminated a great deal of potential corrosion problems. pthomas745 provides a photo of these stubs in “Corrosion of Alde Connectors (see link above).” Unlike the aluminum connection fittings, they probably do not need to be double-clamped. However, I double-clamped almost every connection, from an abundance of caution. I prefer to over do it rather than have to ever deal with more leaks.

Alde EPDM 22mm I.D. Rubber Hose 35119-00002, sold by the meter, @ $4.37/M.

Connector Pipe 022 (AKA plastic stub connectors), 35119-00119, @ $1.55 per unit.

Band Spring Clip 29mm, 35119-00176, @ $1.03 per unit (and well worth it!). Shipping was quite reasonable for these items, in the quantities noted at the beginning of my post, under $20.

Alde Fluid. There are numerous threads on the forum on this, such as:

Several of these threads discuss the merit of using propylene glycol, with the correct anti-corrosion additives, and the danger of using ethylene glycol fluids. I purchased Truma Transfer Fluid from Amazon. Truma Corp. itself also sells it, at a higher price with steep shipping. NuCampRV sells Alde Fluid, but the shipping charges, at least for me, in Oregon, were $200/gal.! Rhomar Rhogard Ultra may be available from some Ferguson Supply outlets and other hydronic/plumbing supply sources, but normally it is only for commercial buyers, and, because it is concentrated, some of the 5 gallons (10 g when diluted for use) would have to last for up to six years. There is a discouraging lack of affordable options. But, given the time and money for repair, I think following the Truma/Alde recommendation is best. My system took about 2.6 gallons. After flushing the system with compressed air and reassembly, I filled it with distilled water and tested it. I used the hand pump method for filling, mentioned above in the referenced Glycol Exchange Guide. In addition to using the system pump on high speed, I use a drill pump to circulate the fluid at an even brisker speed, for a minute or so, to further purge out the air bubbles. I just fit female hose ends to the clear plastic tubing and stopper assemblies in the Guide. Then push the fluid down the intake hole in the tank while sucking it through the pump from the tank reservoir.

After testing, I again air-flushed out 2.6 gallons of water, then refilled with the same quantity of Truma Transfer Fluid.

While I had the convectors exposed I added these two 3.5” fans directly under the rear convector, wired them to a 12 V DC to 5 V DC USB converter, and from there to a switch. I spliced into the DC circuit for the Alde to do this.

From Truma Corp (now owners of Alde), I ordered 80 29 mm spring band clamps, 30 plastic stub connectors, and 3 meters of Alde EPDM 22 mm I.D. hose.

I cut 4 corroded ends off of convectors. Two were on the convector under the bathroom, nearest the stub where the tube tore and leaked, almost at the expansion tank return. I suspect that the transfer fluid farthest from the pump refreshed less over time and allowed more corrosion.

As part of the system rebuild, I covered all convector ends and the check-valve stub connector, which is aluminum, with adhesive-lined heat-shrink tubing. I also double-clamped almost all connections, 3 centimeters in, and at the tube ends. I reused all 90 degree rubber tube pieces, which were undamaged, but cut the ends off of all straight hose pieces, many of which had bulged with corroded aluminum oxide. By using a new piece of rubber tubing for the longest (2 meters, approx.) section, then using my slightly shortened pieces for every shorter section, sequentially, I only needed to buy 3 meters of hose.

Finally, I added two switched 3.5” computer fans just below the convector at the back of the trailer, behind the bed. This convector is the longest, but often partially blocked by bedding, and I thought it could use a boost.

This job was time-consuming, involving lots of awkward and cramped working positions. However, I think it was much more feasible DIY, and I was more successful, because of the multiple contributions and threads of others who have serviced and repaired their Alde systems.

What follows are notes on the rebuild process and components used, along with references to other threads which were the source of the methods used and choices made.

First, the DIY Alde Glycol Exchange Guide by ScottG, available here:

This is invaluable, for removing, flushing, and adding fluid. I used the copper tubes connected to clear plastic hose, described in the Guide, to flush out the fluid without disconnecting any hoses, by using forced air connected to the hose going to the expansion tank intake for the boiler and a bucket under the hose connected to the expansion tank return opening. I put a garden-hose female end on the in-hose, and connected it to a compressor with this:

I got the idea from rh5555 in the thread Alde System Corrosion:

I used adhesive-lined heat shrink tubing to cover aluminum convector ends and the check-valve stub, following BrianZ, although he is not the only one to mention it, in the voluminous thread Corrosion of Alde Connectors:

This thread also refers to different types of coatings people have used to protect convector ends as does this specific thread: How to Repair Corrosion on Alde Convectors, by grassgd.

I used the heat-shrink tube method because I thought it would compensate well for the minor corrosion pitting on the convector ends that I chose not to cut off (all but four of them). Also, it was easier for me than painting. However, it does make using spring band clamps more challenging. Also, it would be wise to use a heat-shrink tubing material that is heat-resistant above 135 degrees.

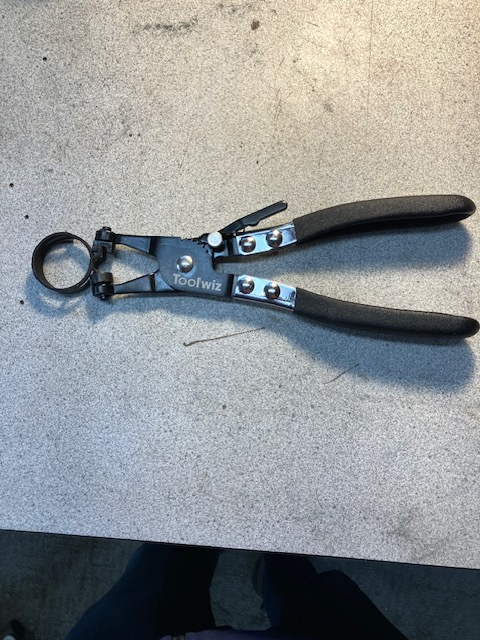

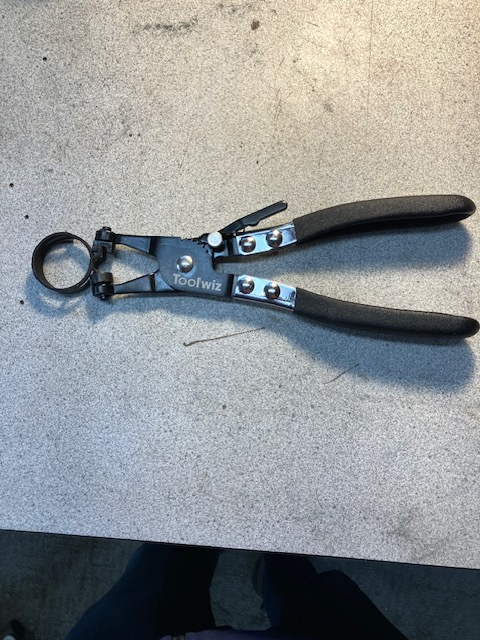

Spring Band Clamps (or Clips) First, a word about using worm-gear clamps instead. The problem with the latter is that the user may under or over-tighten them. When over-tightened, their sharp edges can cut into tubing. Also, road vibration may cause the clamps to loosen. Spring band clamps do not have these problems, and they apply more uniform pressure than worm-gear clamps, and the correct amount if they are OEM parts. The spring band clamps I saw on Amazon did not appear to be robust enough, according to specifications and comments. But the Alde clamps are great: high tensile, coated, thick metal (probably about 0.75mm) and just the right I.D. diameter and pressure design. Moreover, they have been redesigned since the ones I have from the 2017 installation. The rubber Alde hose O.D. is about 26.5 mm. The original clamps opened to an I.D of 27 mm, making them very difficult to slide over tubing expanded around heat-shrink treated convector ends. The new 29 mm clamps are redesigned to open to 29 mm but still clamp down to the same 26.5 mm I.D. Even so, I used dish soap on the outside of pipes on convector fittings to facilitate clamp installation. I double-clamped aluminum fittings, as suggested in many threads, including Corrosion of Alde Connectors, above. An invaluable tool for installing and removing spring band clamps are Hose Clamp Pliers:

Alde started using plastic stub connectors instead of aluminum ones, probably around 2021, when they recommended switching from Century Transfer Fluid to Rhomar Water RG-RTU-50, aka Truma/Alde Transfer Fluid. This change eliminated a great deal of potential corrosion problems. pthomas745 provides a photo of these stubs in “Corrosion of Alde Connectors (see link above).” Unlike the aluminum connection fittings, they probably do not need to be double-clamped. However, I double-clamped almost every connection, from an abundance of caution. I prefer to over do it rather than have to ever deal with more leaks.

Truma Corporation now owns Alde. The former has a service center in Elkhart Indiana, and their parts department staff are very helpful. Their phone number is +1-855-558-7862. I was made aware of this number by ReenieG in the thread Glycol Tubing Size:

They will not sell some Alde parts direct to users, only to dealers, and their inventory numbering is different from Alde’s. But the basic system parts are available. Here are the numbers for the parts I purchased:

Alde EPDM 22mm I.D. Rubber Hose 35119-00002, sold by the meter, @ $4.37/M.

Connector Pipe 022 (AKA plastic stub connectors), 35119-00119, @ $1.55 per unit.

Band Spring Clip 29mm, 35119-00176, @ $1.03 per unit (and well worth it!). Shipping was quite reasonable for these items, in the quantities noted at the beginning of my post, under $20.

Alde Fluid. There are numerous threads on the forum on this, such as:

Changing Out the Alde Fluid

Alde Fluid:

High Cost of Rhomar Exchange:

Several of these threads discuss the merit of using propylene glycol, with the correct anti-corrosion additives, and the danger of using ethylene glycol fluids. I purchased Truma Transfer Fluid from Amazon. Truma Corp. itself also sells it, at a higher price with steep shipping. NuCampRV sells Alde Fluid, but the shipping charges, at least for me, in Oregon, were $200/gal.! Rhomar Rhogard Ultra may be available from some Ferguson Supply outlets and other hydronic/plumbing supply sources, but normally it is only for commercial buyers, and, because it is concentrated, some of the 5 gallons (10 g when diluted for use) would have to last for up to six years. There is a discouraging lack of affordable options. But, given the time and money for repair, I think following the Truma/Alde recommendation is best. My system took about 2.6 gallons. After flushing the system with compressed air and reassembly, I filled it with distilled water and tested it. I used the hand pump method for filling, mentioned above in the referenced Glycol Exchange Guide. In addition to using the system pump on high speed, I use a drill pump to circulate the fluid at an even brisker speed, for a minute or so, to further purge out the air bubbles. I just fit female hose ends to the clear plastic tubing and stopper assemblies in the Guide. Then push the fluid down the intake hole in the tank while sucking it through the pump from the tank reservoir.

After testing, I again air-flushed out 2.6 gallons of water, then refilled with the same quantity of Truma Transfer Fluid.

While I had the convectors exposed I added these two 3.5” fans directly under the rear convector, wired them to a 12 V DC to 5 V DC USB converter, and from there to a switch. I spliced into the DC circuit for the Alde to do this.

Comments

As I have a 2019 400 I am concerned at how much disassembly of cabinets, etc you had to do to reach each of the convectors. The one under the bath floor pan I can barely reach, and I can't imagine taking the bath room walls apart.

2019 T@B400 Boondock Lite "Todd"