Best Of

Re: Help a Frozen Floridian

Alde Convector & Hose Rebuild, Useful Truma/Alde part numbers, and a Modest System Improvement

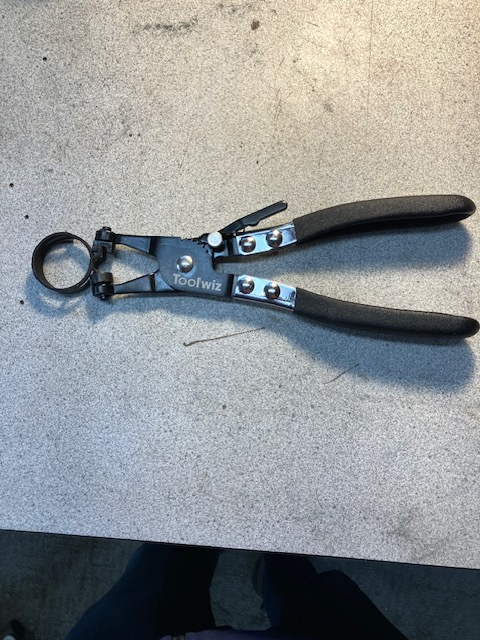

From Truma Corp (now owners of Alde), I ordered 80 29 mm spring band clamps, 30 plastic stub connectors, and 3 meters of Alde EPDM 22 mm I.D. hose.

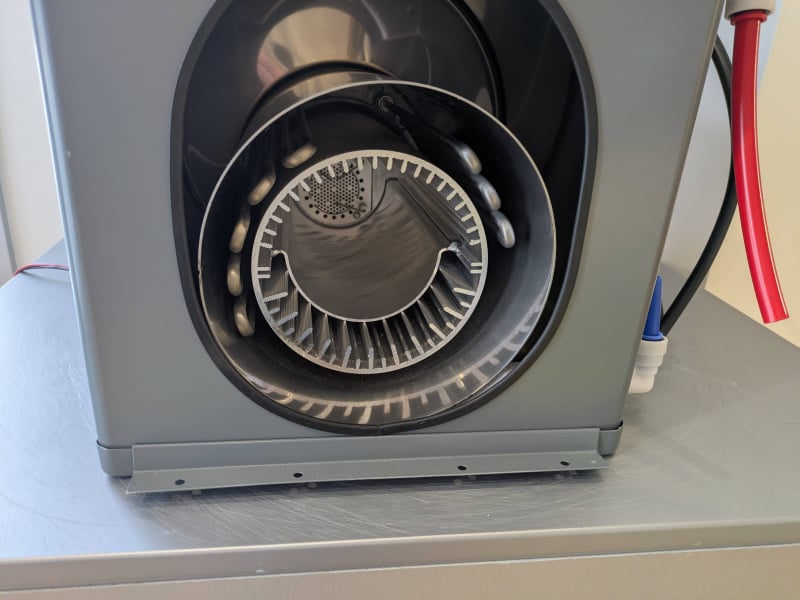

I cut 4 corroded ends off of convectors. Two were on the convector under the bathroom, nearest the stub where the tube tore and leaked, almost at the expansion tank return. I suspect that the transfer fluid farthest from the pump refreshed less over time and allowed more corrosion.

As part of the system rebuild, I covered all convector ends and the check-valve stub connector, which is aluminum, with adhesive-lined heat-shrink tubing. I also double-clamped almost all connections, 3 centimeters in, and at the tube ends. I reused all 90 degree rubber tube pieces, which were undamaged, but cut the ends off of all straight hose pieces, many of which had bulged with corroded aluminum oxide. By using a new piece of rubber tubing for the longest (2 meters, approx.) section, then using my slightly shortened pieces for every shorter section, sequentially, I only needed to buy 3 meters of hose.

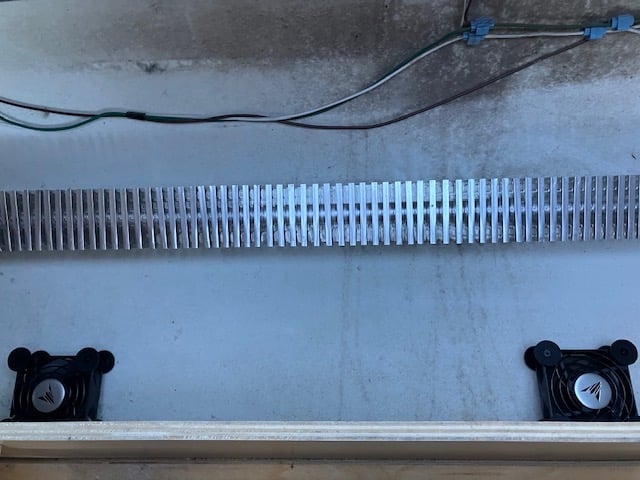

Finally, I added two switched 3.5” computer fans just below the convector at the back of the trailer, behind the bed. This convector is the longest, but often partially blocked by bedding, and I thought it could use a boost.

This job was time-consuming, involving lots of awkward and cramped working positions. However, I think it was much more feasible DIY, and I was more successful, because of the multiple contributions and threads of others who have serviced and repaired their Alde systems.

What follows are notes on the rebuild process and components used, along with references to other threads which were the source of the methods used and choices made.

Alde started using plastic stub connectors instead of aluminum ones, probably around 2021, when they recommended switching from Century Transfer Fluid to Rhomar Water RG-RTU-50, aka Truma/Alde Transfer Fluid. This change eliminated a great deal of potential corrosion problems. pthomas745 provides a photo of these stubs in “Corrosion of Alde Connectors (see link above).” Unlike the aluminum connection fittings, they probably do not need to be double-clamped. However, I double-clamped almost every connection, from an abundance of caution. I prefer to over do it rather than have to ever deal with more leaks.

Alde EPDM 22mm I.D. Rubber Hose 35119-00002, sold by the meter, @ $4.37/M.

Connector Pipe 022 (AKA plastic stub connectors), 35119-00119, @ $1.55 per unit.

Band Spring Clip 29mm, 35119-00176, @ $1.03 per unit (and well worth it!). Shipping was quite reasonable for these items, in the quantities noted at the beginning of my post, under $20.

Alde Fluid. There are numerous threads on the forum on this, such as:

Several of these threads discuss the merit of using propylene glycol, with the correct anti-corrosion additives, and the danger of using ethylene glycol fluids. I purchased Truma Transfer Fluid from Amazon. Truma Corp. itself also sells it, at a higher price with steep shipping. NuCampRV sells Alde Fluid, but the shipping charges, at least for me, in Oregon, were $200/gal.! Rhomar Rhogard Ultra may be available from some Ferguson Supply outlets and other hydronic/plumbing supply sources, but normally it is only for commercial buyers, and, because it is concentrated, some of the 5 gallons (10 g when diluted for use) would have to last for up to six years. There is a discouraging lack of affordable options. But, given the time and money for repair, I think following the Truma/Alde recommendation is best. My system took about 2.6 gallons. After flushing the system with compressed air and reassembly, I filled it with distilled water and tested it. I used the hand pump method for filling, mentioned above in the referenced Glycol Exchange Guide. In addition to using the system pump on high speed, I use a drill pump to circulate the fluid at an even brisker speed, for a minute or so, to further purge out the air bubbles. I just fit female hose ends to the clear plastic tubing and stopper assemblies in the Guide. Then push the fluid down the intake hole in the tank while sucking it through the pump from the tank reservoir.

After testing, I again air-flushed out 2.6 gallons of water, then refilled with the same quantity of Truma Transfer Fluid.

While I had the convectors exposed I added these two 3.5” fans directly under the rear convector, wired them to a 12 V DC to 5 V DC USB converter, and from there to a switch. I spliced into the DC circuit for the Alde to do this.

Re: Post up some shots of your T@B set-up at the camp site! #3

2023 400 - Painting the Dots

New TAB Owner Resource

I've spent some time fixing that and am excited to share my new TAB Owner Resource Guide. It takes all that disconnected content and arranges it into a logical journey. It’s designed to walk you through the key things you need to know, providing helpful tools along the way:

- Performing your first "shakedown" trip to test all the systems.

- A step-by-step guide to hitching, unhitching, and setting up your campsite.

- Interactive guides and printable checklists to help you master the electrical, water, and Alde/Truma systems. this includes a new interactive tool to model your power use and how long your battery will

This is not a replacement for the nuCamp manual or the manuals that come with the different components in your TAB - this is information that I have found helpful. You should always defer to nuCamp and manufacturer advice.

My sincere hope is that this guide makes the learning curve a little less steep and helps you avoid some of the common mistakes we all make. The goal is to make your first few trips less stressful and more fun.

Happy camping!

TAB New Owner Resource Guide - Jenn Grover

Re: Is Plug-in Solar Feasible for a T@B?

Modification to access yellow flappers from Nautilus

I used an electrical lug to transition from the 1/4" aluminum rod linkage to the flapper handle. Drilled a hole in the flapper, ran a screw thru the handle, then a flat washer and then 2 hex nuts. The first nut is not tightened to the handle but left loose so there is play. The 2nd nut is tightened to the first nut as a jam nut to ensure this loose interface stays on the handle.

I had some 1/4" rod laying around but I see that, plus the other parts, are available on Amazon -lug, universal joint, etc.

I wanted to make sure that the pressure relief would still function hence the rather loose connection, the weight of the linkage is minor compare to the pressure at the trip point.

Works well so far.

Re: Has anyone purchased and received a Haven?

Lawyerboy said:Our dealership in Florida said he would have one on the lot last month which didn’t happen. Just curious if folks took the plunge and how it performs. Morning

Ordered our Haven mid Oct and took delivery on 3 Dec which was about the time our Dealership and nucamp estimated. We had it home three days packing and then launched on a two week RV trip - shake down. As with anything new, we had a few issues but nothing that derailed our trip. The Haven has the new ALDE 3030 but no physical manuals were provided. Everything is linked to QR codes, so as soon as we got home we started printing (this is our third nucamp trailer and we knew far more than the PTI tech at the dealership). We ordered the upgraded solar package and spent an hour looking through the paperwork provided to find the PIN codes so we could monitor the Victron unit through the app. The Garmin remote for the radio refuses to pair and the circular light in the shower stopped working day one. Vent works but the light stopped. Nucamp has sent us a new one. I also spent time removing the thousands (pun) of screws in the bench seat over the ALDE system. I want quick access if needed, plus the lever to drain the ALDE is there. Removed half the screws in the bench over the Victron. The back bench area has a nice storage area. The bed felt like sleeping on wood but fortunately, my smart wife had already ordered a pad and something else so the bed was actually comfortable. The heat from the ALDE is radiant, so it takes a bit of time to heat up the camper. What we started doing is set it to 80 and it heats fast, then dial it down to a comfortable level. Through the Alde 3030 you can link the AC and ALDE heat and set a temp and the two units will work together to keep your rig at whatever temp you set. The top cabinets are high for my vertically challenged wife, but she found a small stool that folds flat that gives her the perfect reach. The dry bath is very nice and as a 6'2" 230 guy, I had no issues using the shower. After using the rig for two weeks, there are a few things we would change; the only USB/USB-C connections are on each side of the bed (side note, the storage around and under the bed is AWESOME according to my wife). These sort of ports are needed in the dinette area but we used a small power strip with ac/usb/usb-c connections to temp solve the problem. The two steps into the rig are terrible Not sure the fix but I wonder if a single step of the heavy caliber as offered on the new nucamp rigs might work. We also thought it would have been a nice touch to add under carriage lights similar to what is on the new 400s. There is a switch inside that needs to be turned on to power the rearward facing camera. The auto awning is nice and the awning lights really light up the area at night. The electric trailer jack is nice but never have owned/operated one, I can't tell whether ours is slow or the speed is normal. Storage / garage area is awesome. Things that use to go into the bed of our tow truck, now are stored in the Haven garage, making pre and post packing much easier. The fridge is the same size (dimension) of our 2019 t@b 400, but it's missing all the stuff our 400 had like propane and AC components. This for us doubled the interior; on one shelf we got a small pizza box and in the freezer, we got two 1qt bags of ice with room to spare. The freezer width isn't that great but it's depth is impressive. The sewer hose is stored in a compartment in the rear bumper. This compartment does not extend the full length of the bumper; so we were only able to put a 10' sewer hose and our black water flush hose inside. The other 10' section is in a small rubber made box in the front storage tub. We pulled the Haven with a 2020 F150 5.0 and on our first 1000 mile trip, it pulled as easily as our 400 ever did. Our 400 had served us well with us traveling over 50k miles to include two trips from FL to AK with it. But as we aged, the crawling over each other to the late night bathroom runs was proving more of a challenge and having the luxury of being able to make the bed without having to crawl on the bed itself were things we wanted. Similar trailers like an Air Stream were out of our budget range. I did buy a large cover to use on the Haven when it's in storage. Had to use our large ladder and it took my wife and I about 30-mins to get it installed but it is well worth the effort to protect the unit from the sun here in FL. Be happy to share our experiences and lessons from our first trip with anyone if they are interested.

Re: Recommendation for best size portable solar panel

For us, having enough battery capacity to go a week (or more) with limited solar availability was important. Next was to have enough solar to recoup our daily power usage (up to 50Ah per day) even with poor solar conditions. To meet that, we move up to a 400W Renogy suitcase. We also have rooftop solar, but don't count on it since we try to park in the shade.

We've also carried a little 25lb, 700W propane generator for emergency charging, but have been bringing it less and less since its lack of use makes it hard to justify. Worst case, we have to hit a spot with an electric hookup every week or two.

Trip to Elkhart to See Truma

Below is an account of my experience with having the good folks at Truma service my Alde unit. I took my 2018 T@b 320 to their service center in Elkhart and I thought this may be helpful to folks here.

I just acquired the camper this fall and the previous owner let me know that the propane heat was not working. I was also not sure when the last glycol flush had been done. So my goals for the work included having the system fully flushed with the newest glycol added, having the propane heat looked at, any misc items that needed to be addressed, and generally learning more about the system. I can say that all of those goals were achieved and I was very happy with their service and expertise.

As far as accomodations I had booked an electric site at the RV Hall of Fame Museum. However, when I got there I was informed that the electric sites were closed up sometime in November. They also said I could stay the night if I did not need electric. However, since I was having issues with propane heat and the fact that it would get down to 4 degrees fahrenheit overnight I skipped it and grabbed a motel. There are lots of motel options 3-5 miles from the shop. Also, being an RV town there are quite a few campgrounds in the general area when in season. A bonus option is that Truma also has 2 electric spots with in-season water that you can reserve the night before your appointment.

I should also mention that Truma has a Florida service center. The Truma folks said that it's their quiet time in Elkhart now but that the Florida one is starting to get really busy. This flip flops in the spring.

The actual appointment was about 3 hours. The work was all done indoors in their climate controlled warehouse. They had me sit out in the waiting area which also doubles as an area with displays of all of their products. The display units are interesting in that they are cutaway models and show all of the chambers within the Alde. This became very helpful because my service tech was giving me updates as he went along. He would come in from the warehouse and use the cutaway display model to explain how the system works.

One of the first things the service tech checked was the propane situation. He isolated my issue by connecting his own propane bottle with a hose directly the Alde. It fired right up and showed no issues. He said all I'll need is to order a regulator and replace the one on the front of the T@b. He recommended a high flow, double chamber unit readily available on Amazon.

Next came the flush. He did not think it had been flushed in quite awhile. The tale tell sign was that 3 of my aluminum thru-pipes were corroded and beginning to swell. 1 of the thu-pipes is actually a check flow valve and was pretty buggered up. The other 2 simply connect 2 of the black heating tubes. I had those all replaced and the cost and labor was nominal but was in addition to the cost of the flush. The other problem that he noted was that there was a decent amount of sediment in the glycol. He said that the method he used was to flush lots of water through the system using several of the openings and attempting to get as much of it out as possible. After that he was able to start pumping in the new glycol and replacing the water.

As far as purchasing a bottle of glycol the tech gave me a small bottle to use to top off the level (I believe it's about 8 oz). He said there would be some small air bubbles for a while that will work their way out and these would cause the level to go down a bit. However, after a while it should not use up anymore glycol and that there's no reason to buy a bigger gallon jug.

Of course it can't be said enough that one of the big benefits of having the manufacturer service the unit is all of the helpful tips. For example, I did not know that the big black tubes are supposed to not have anything on or around them. The tubes actually put off heat and assist in warming up the spaces they run through. It was also helpful to see a cutaway version of the unit. The inner chamber is heated up by the burner, the middle one is where the glycol circulates, and the outer area is for the water. He did emphasize that if you're using electric to first start it with propane to get it up to temp, then switch to electric to maintain it. Along those lines, mine has 2 electric "levels". He said there are 2 heating elements and to always run both.

Some other tips he shared was to always keep the yellow drain valve open when it's winterized. The thought there was that there is always a chance someone may operate the water pump and potentially pump some water into the unit, which may freeze up and cause issues. He also showed me that the lowest spot is where the cold water (blue) pipe goes in. As far as using the propane in the winter, he recommended using a propane tank warmer.

The last and most important recommendation was to come back in 3 years to have the glycol flushed again. 3 years being for your average part-time occasional camper, 2 years for full-time or more serious folks.

So in summary, I can't recommend enough to contact Truma and have these folks go through these excellent heaters. They are great folks to work with and you will learn a lot.